HAMBURG- European Plane Marker Airbus has inaugurated a cutting-edge assembly line for the A321XLR in Hamburg, marking a significant milestone in the aircraft’s production ramp-up.

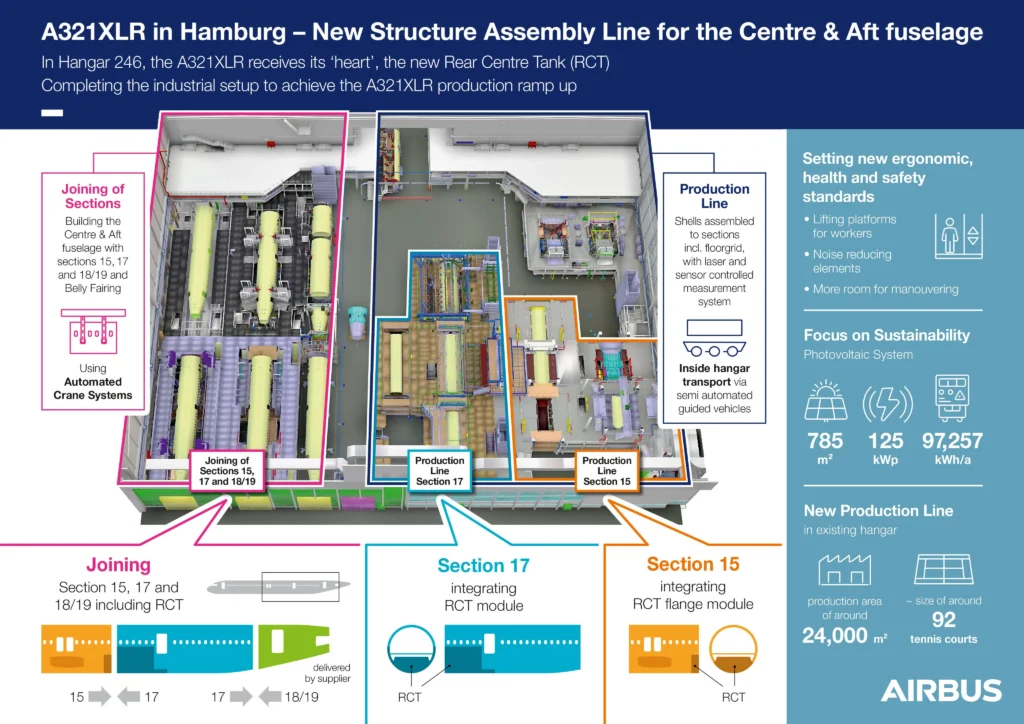

The new structure assembly line, located in Hangar 246, focuses on the center and aft fuselage sections of the long-range single-aisle jet.

Airbus A321XLR Assembly Line

The 24,000-square-meter facility, formerly used for A380 production, now hosts the joining of sections 15, 17, and 18/19 of the A321XLR.

At the heart of this operation is the installation of the aircraft’s “heart” – the new 13,000-liter Rear Centre Tank (RCT). This crucial component gives the A321XLR its extended range capabilities.

Airbus has implemented several innovative features in the new assembly line:

- Automated crane systems for efficient section joining

- A production line with shells assembled to sections, utilizing laser and sensor-controlled measurement systems

- Semi-automated guided vehicles for internal hangar transport

The facility also sets new standards for worker safety and comfort, featuring:

- Lifting platforms for improved ergonomics

- Noise-reducing elements

- Increased maneuvering space for workers

Sustainability plays a key role in the new assembly line. Airbus has installed a photovoltaic system covering 785 square meters, generating 125 kWp and producing 97,257 kWh/a of clean energy.

This new assembly line complements the Equipment Installation facility in Hangar 259, which opened last year. Together, these developments complete the industrial setup necessary for the A321XLR’s production ramp-up.

Delivery in Q3 2024

Airbus remains on track to deliver the first customer A321XLR to Iberia (IB) in the third quarter of 2024, pending certification from the European Union Aviation Safety Agency (EASA).

The A321XLR’s production in Hamburg demonstrates Airbus’s commitment to innovation and efficiency in aircraft manufacturing, positioning the company to meet growing demand for long-range, single-aisle aircraft in the coming years.

The A321XLR has emerged as a top seller for Airbus, with orders soaring to approximately 550 units. An Airbus representative stated, “We’ve secured around 550 orders, which is impressive for a product at this stage.”

The new production space spans an area equivalent to 90 tennis courts, highlighting the significant scale of the operation. Airbus has also prioritized sustainability in the facility’s design.

A rooftop solar system now generates a portion of the electricity needed for aircraft construction, reducing the environmental impact of the manufacturing process.

Join us on Telegram Group for the Latest Aviation Updates. Subsequently, follow us on Google News.